Automatic Honeycomb Board Line

Features of Honeycomb Board Line

- High in automation, low process wastage, rate of finished honeycomb paperboard up to 99%, hence an equipment of high-tech content.

- The machine of honeycomb board line is easy to operate, with the control of computerized touch screen, and we take the lead in realizing continuous production from paper feeding to finished products.

- Wholly computerized control, and internationally fairly advanced coating technology is used and pneumatic, optical and electromechanical integrative to make the quality more reliable and stable.

- Fairly great technical breakthrough in the design, and more rational, hence high output, considerable cost decline, 4 to 5 workers of single shift can produce about 10,000 square meters.

- Dust-free, odor-free and pollution-free, in compliance with the requirements of environment protection.

- Without inter medium work process, the whole process of honeycomb board line can be controlled, hence manpower is greatly reduced and full-automatic production can be truly realized.

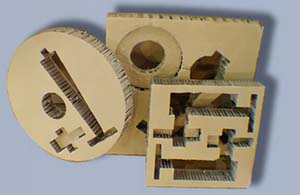

Samples

Board-case

Board-case Lining-mode

Lining-mode

Furniture 1

Furniture 1 Furniture 2

Furniture 2

Package

Package Walls

Walls

Pallets

Pallets Pallets 2

Pallets 2

| Specifications of honeycomb board line | ||

| Width of core paper roll | max | 2,000 mm |

| Width of core surface paper | max | 1,600 mm |

| Finished paperboard thickness | 8-80 mm | |

| Honeycomb’s side length | 4 – 16 mm | |

| Production speed | 6-25 m/min | |

| Transverse cutting knife speed | 380 times/min | |

| Heating mode | steam heating, hot air cycling | |

| Equipment power | 80 kW | |

| Overall dimensions | 74 × 3.6 ×3.2 m | |

| Equipment weight | 62 Ton | |

Company introduction:

As a professional honeycomb board machine manufacturer, Lantytk® Corp isa professional provider of solution for the Corrugated Industry. Our core characteristics include competence, innovation and a tireless commitment to meeting customers’ needs, thus making us a strong and reliable partner in the industry.

Related Products:

- Home

- Machinery

- Corrugator

- Corrugator Line

- -Roll Stand

- -Preheater

- -Single Facer

- -Glue Machine

- -Bridge

- -Double Facer

- -Slitter Scorer

- -Cut-off

- -Downstacker

- -Starch system

- Honeycomb Board Line

- Paper Machine

- Waste Paper Processing

- Finishing

- Sheet-fed Die Cutter

- -Die-cutter

- -Stripping Machine

- Rotary Die Cutter

- Automatic Creaser

- Printer Slotter

-

Email: landy.sh137@gmail.com

Roll Stand

Roll Stand Preheater

Preheater Single Facer

Single Facer Glue Machine

Glue Machine Bridge

Bridge Double Facer

Double Facer Slitter Scorer

Slitter Scorer Cut-off

Cut-off Downstacker

Downstacker Starch system

Starch system