Waste Paper Processing Line

Final product of waste paper processing line

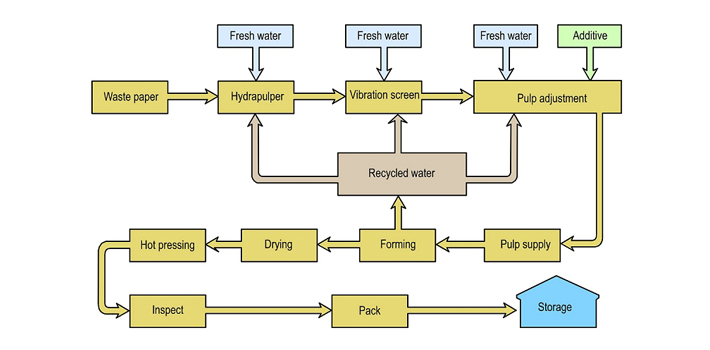

Profile of waste paper processing line

The waste paper processing line is designed for processing the waste paper from the corrugated board line and others. With the trend of environmental protection and sustainable development, most of products need to be recycling for expressing full potential. What we do, is to convert waste paper to paper trays for eggs, fruits, cups, bottles, etc., packages, protector used in industrial or medicine packages, daily necessities, molded products, etc.

It makes full use of paper in the production as well as a great contribution to the environmental protection, maximizing the profit in the competitive market.

Processing capacity of the waste paper processing line is determined by the quantity of waste paper, from 30 kg/hour to 150 kg/hour (determined by different products). And the fuel used in drying could be chosen in the scope of diesel, nature gas and LPG, for meeting different requirements from customers.

- Home

- Machinery

- Corrugator

- Corrugator Line

- -Roll Stand

- -Preheater

- -Single Facer

- -Glue Machine

- -Bridge

- -Double Facer

- -Slitter Scorer

- -Cut-off

- -Downstacker

- -Starch system

- Honeycomb Board Line

- Paper Machine

- Waste Paper Processing

- Finishing

- Sheet-fed Die Cutter

- -Die-cutter

- -Stripping Machine

- Rotary Die Cutter

- Automatic Creaser

- Printer Slotter

-

Email: landy.sh137@gmail.com

Roll Stand

Roll Stand Preheater

Preheater Single Facer

Single Facer Glue Machine

Glue Machine Bridge

Bridge Double Facer

Double Facer Slitter Scorer

Slitter Scorer Cut-off

Cut-off Downstacker

Downstacker Starch system

Starch system