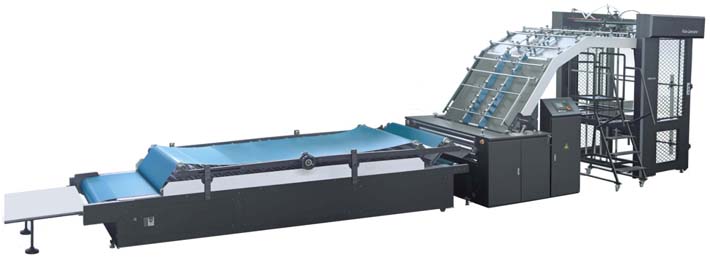

Semi-automatic Flute Laminating Machine

Features of flute laminating machine

- Heightened top sheet feeder enable bottom sheet loading without production stop.

- Turn-up bridge plate is convenient for cleaning; discontinuous water-circulating system ensures washing clean.

- Automatic feeding is for bottom sheet and manual feeding is for cover sheet. (Feeding from side for cover sheet is optional)

- Flexible front register avoid bottom sheet exceeding the cover sheet. It is adjustable for the front-and-rear lamination between bottom sheet and cover sheet.

- Bottom sheet can be the paperboard above 350 gsm, or A/B/C/D/E/F corrugated cardboard.

- The corrugated cardboards are pressed by intelligent control, with features like energy-saving and adjustable space of piling.

- It adopts high-precision glue blocking device, for saving glue.

- Optional items: PLC control, lengthened pressing unit and auxiliary lifting platform for cover sheet loading.

| Specifications of flute laminating machine | ||

| Model | LMS-145 / LMS-165 | |

| Sheet size | max | 1,450 x 1,100 mm / 1,650 x 1,300 mm |

| Power | 8.5 kW / 10 kW | |

| Speed | 0 - 90 m/min | |

| Weight | 3,400 kg / 3,600 kg | |

| Dimensions | 9.00 x 2.17 x 1.90 m / 9.00 x 2.37 x 1.90 m | |

2. Automatic flute laminating machine

Characteristics of flute laminating machine

- Automatic feeders for both cover sheet and bottom sheet.

- PLC HMI achieves easy operation and troubleshooting in running, the safety devices equipped guarantee the human life of operator. The main gears and electric components adopt famous brands products imported for ensuring steady running.

- Elastic front lay avoids bottom sheet exceeding from the cover sheet; the front-and-back distance between cover sheet and bottom sheet is adjustable.

- It is suitable for laminating cardboard (above 450 gsm) to cardboard, cardboard to A/B/C/D/E corrugated cardboard and corrugated cardboard to corrugated board.

- Registration system for cover sheet, to improving the precision.

| Specifications of flute laminating machine | ||

| Model | LMA-145 / LMA-165 | |

| Sheet size | max | 1,450 x 1,100 mm / 1,650 x 1,650 mm |

| min | 400 x 400 mm | |

| Power | 15 kW / 22 kW | |

| Weight of cover sheet | 200 - 450 gsm | |

| Laminating tolerance | ± 1.5 mm | |

| Speed | max | 5,500 s/h |

| Weight | 6,200 kg / 6,500 kg | |

| Dimensions | 12,76 x 2.40 x 2.56 m / 12,76 x 2.60 x 3.00 m | |

Company introduction:

Lantytk® Corp isa professional provider of solution for China cardboard laminator. Our core characteristics include competence, innovation and a tireless commitment to meeting customers’ needs, thus making us a strong and reliable partner in the industry of flute laminating machine.

Related Products:

- Home

- Machinery

- Corrugator

- Corrugator Line

- -Roll Stand

- -Preheater

- -Single Facer

- -Glue Machine

- -Bridge

- -Double Facer

- -Slitter Scorer

- -Cut-off

- -Downstacker

- -Starch system

- Honeycomb Board Line

- Paper Machine

- Waste Paper Processing

- Finishing

- Sheet-fed Die Cutter

- -Die-cutter

- -Stripping Machine

- Rotary Die Cutter

- Automatic Creaser

- Printer Slotter

-

Email: landy.sh137@gmail.com

Die-cutter

Die-cutter Stripping Machine

Stripping Machine Rotary Die Cutter

Rotary Die Cutter Automatic Creaser

Automatic Creaser R Series Automatic

R Series Automatic J Series Automatic

J Series Automatic X Series Automatic

X Series Automatic S Series Semi-automatic

S Series Semi-automatic Laminator

Laminator Partition Assembler

Partition Assembler Carton Stitcher

Carton Stitcher Strapping Machine

Strapping Machine Stretch Maching

Stretch Maching Folder Gluer for Corrugated Board

Folder Gluer for Corrugated Board  Semi-auto Carton Gluer

Semi-auto Carton Gluer